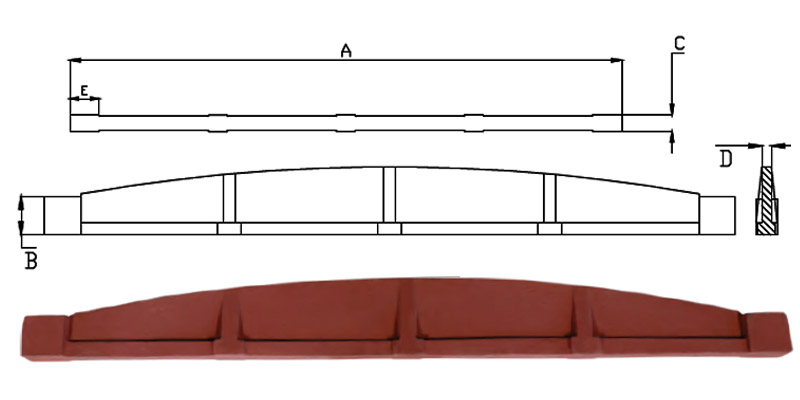

These grate bar are used in the furnace upon which the fuel is burned. These bars are manufacture with various alloy compositions, depends on the fuel used in the boiler. Theintermittent gap in the grate bar / fire bars allows the air flow for combustion. Proper selection of the gap is necessary to avoid the fuel from falling down, while burning.

| DIMENSIONS IN MM | |||||

| SR NO | A | B | C | D | E |

| G1 | 530 | 45 | 32 | 12 | 36 |

| G2 | 890 | 47 | 32 | 12 | 47 |

| G3 | 822 | 45 | 32 | 8 | 45 |

| G4 | 730 | 50 | 32 | 8 | 45 |

| G5 | 1010 | 50 | 32 | 8 | 45 |

| G6 | 540 | 45 | 35 | 12 | 50 |

| G7 | 615 | 45 | 35 | 12 | 50 |

| G8 | 690 | 45 | 35 | 12 | 50 |

| G9 | 578 | 45 | 32 | 12 | 55 |

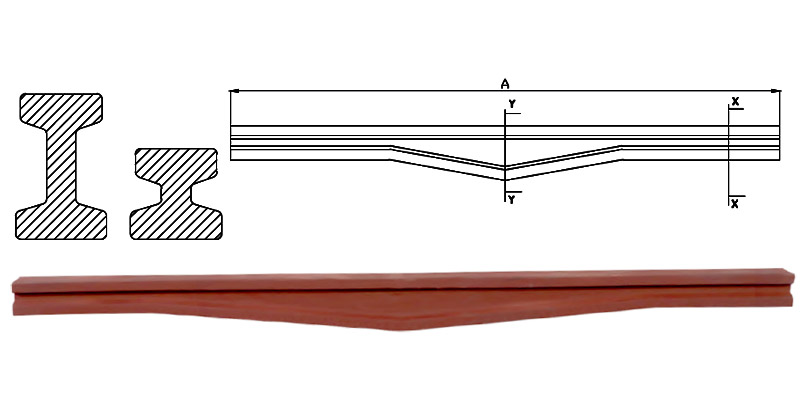

| DIMENSION IN MM | |

| SR NO | A |

| S1 | 740 |

| S2 | 1066 |

| S3 | 1422 |

| S4 | 1132 |

| S5 | 940 |

| S6 | 1280 |

| S7 | 1120 |

| S8 | 800 |

| S9 | 1150 |

| S10 | 1030 |

| S11 | 930 |

| S12 | 1308 |

| S13 | 642 |

| S14 | 860 |

| S15 | 980 |

| S16 | 1010 |

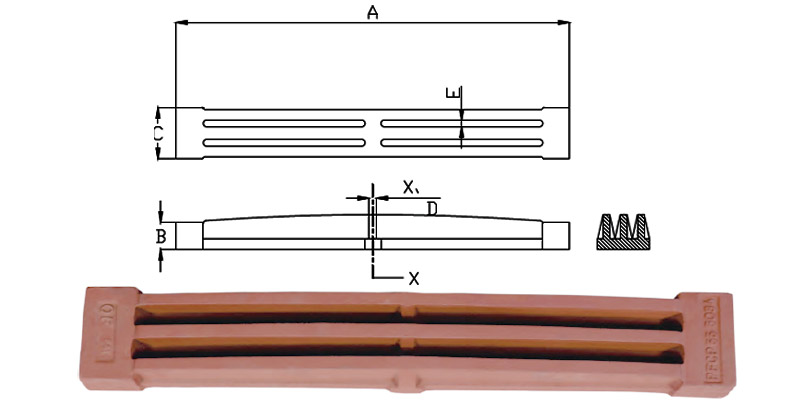

Modified version of single grate bar. Basically three grates bars are combined and manufactured as one piece. A homogeneous construction, allows, more heat dissipation, resulting in better heat resistance. These grate bars generally give a longer life.

| DIMENSION IN MM | |||||

| SR NO | A | B | C | D | E |

| T1 | 730 | 50 | 96 | 15 | 10 |

| T2 | 530 | 50 | 96 | 15 | 10 |

| T3 | 630 | 50 | 96 | 15 | 10 |

| T4 | 690 | 45 | 105 | 15 | 15 |

| T5 | 540 | 45 | 105 | 15 | 15 |

| T6 | 615 | 45 | 105 | 15 | 15 |

| T7 | 690 | 45 | 90 | 15 | 8 |

| T8 | 615 | 45 | 90 | 15 | 8 |

| T9 | 615 | 45 | 96 | 15 | 10 |

| T10 | 540 | 50 | 90 | 15 | 8 |

| T11 | 540 | 50 | 96 | 15 | 10 |

| T12 | 578 | 50 | 90 | 15 | 8 |

| T13 | 578 | 50 | 96 | 15 | 10 |